As we approach 2026, the landscape of equipment tracks is changing rapidly. Each year brings new innovations and trends that impact various industries. Understanding these trends is crucial for businesses looking to stay competitive.

Equipment tracks have evolved significantly. Companies are investing in advanced materials and designs to enhance durability and functionality. This helps reduce maintenance costs over time. However, there are challenges too. Some manufacturers struggle to keep up with the fast pace of technology. They may overlook essential features that enhance efficiency.

Moreover, sustainability is becoming vital in equipment tracks. Companies are prioritizing eco-friendly options. This shift is not just a trend; it's a demand from consumers and regulatory bodies. As we navigate these trends, it’s important to reflect on how they affect our choices. Tracking these developments can lead to smarter, more informed decisions in the future.

The landscape of equipment tracks is evolving rapidly. Emerging technologies are set to redefine how we approach design and efficiency in 2026. One notable trend is the integration of advanced materials. These materials promise durability while remaining lightweight. Think about tracks that reduce wear and tear. This is crucial for industries that rely heavily on their equipment.

Another innovation transforming equipment tracks is smart technology. Sensors embedded in tracks can monitor performance in real-time. Imagine workers receiving instant notifications about wear levels or potential failures. This could prevent costly downtime. However, not all users may embrace this technology at first. There is a learning curve.

Sustainability is also playing a significant role. Eco-friendly tracks are being developed using renewable resources. Yet, the challenge lies in balancing performance with environmental impact. Some products may not perform as expected. This area requires further exploration and innovation. These trends highlight the ongoing transformation in equipment tracks, with potential pitfalls that need addressing.

Sustainability is reshaping equipment track design in 2026. As environmental concerns rise, manufacturers are focusing on eco-friendly materials. Studies show that sustainable materials can reduce carbon footprints by up to 30%. This shift is crucial for meeting stringent regulations.

The push for innovation includes lighter tracks that use recycled components. These adjustments not only lower energy consumption but also improve performance. According to a recent industry report, tracks designed with sustainability in mind have increased efficiency by approximately 20%.

Tips: Consider using local materials for sourcing. This not only cuts transportation emissions but supports the local economy. Collaborate with designers to find sustainable solutions that fit your needs. Rethink traditional designs. Could alternative methods provide better results? Embracing change might yield surprising benefits.

Advancements in materials used for equipment tracks are at the forefront of industry innovation. New composites are improving durability and weight, creating more efficiency. For example, recent studies indicate that advanced rubber compounds can increase track lifespan by up to 30%. These materials resist wear and tear better than traditional options. This is crucial for performance in harsh environments.

Tips: Always consider material compatibility with your machinery. The right choice can save you from costly repairs down the line.

Innovations also include lightweight synthetic materials. These advancements can reduce overall fuel consumption. Reports show that equipment using lighter tracks can achieve a fuel efficiency increase of 15%. However, these materials may not fit every application. Users should evaluate their specific needs before making a decision.

Tips: Test new materials in controlled environments first. This helps ensure they meet expectations. Remember, not every advancement suits every need.

This chart illustrates the trends in materials used for equipment tracks in 2026, highlighting the percentage distribution among various materials. The data indicates a growing preference for natural and synthetic rubber, along with an emerging interest in reinforced plastics.

Safety is crucial in equipment track systems. Recent innovations focus on enhancing this aspect significantly. For instance, sensor technologies are now integrated into tracks. These sensors can detect obstacles and prevent collisions. They improve situational awareness for operators and ensure better safety for personnel on-site.

Moreover, improved materials are being used in track construction. These materials not only enhance durability but also reduce the risk of malfunctions. Tracks made from advanced composites offer better performance under various conditions. However, there's still a need for further testing and refinement. Some users report inconsistencies in performance during harsh weather.

User training plays a vital role in safety. Operators must understand the capabilities and limits of their equipment. Regular drills and assessments can help reinforce safety protocols. Still, the gap between knowledge and application often exists. Continuous improvement in training programs is essential to bridge this gap effectively.

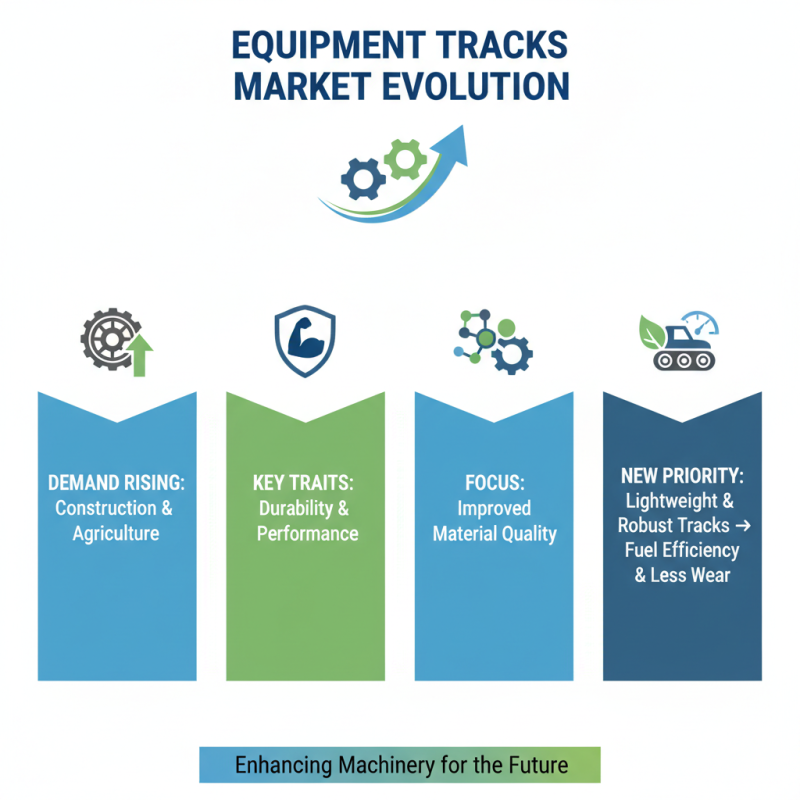

The equipment tracks market is evolving rapidly. Demand is rising across industries like construction and agriculture. A mix of durability and performance is essential in these products. Companies must focus on improving material quality to meet customer expectations. Lightweight yet robust tracks are becoming a priority. This shift aims to enhance fuel efficiency and reduce wear and tear on machinery.

Future predictions suggest a growing interest in eco-friendly solutions. More users are looking for sustainable materials. Innovations in recycling may reshape the industry landscape. However, the transition can be challenging. Manufacturers should invest in research to explore new options. Listening to consumer feedback will be crucial for adaptation. Not every company is ready to make these changes, which may lead to missed opportunities.

Additionally, there is an increasing reliance on technology. Smart features in equipment tracks can boost efficiency. Yet, some companies may overlook this trend, focusing instead on traditional methods. This short-sightedness could hinder progress. Suppliers must balance innovation with proven practices, finding a path that embraces change while respecting the legacy of the industry.